|

Medical |

CO2 Incubator Control System

Specification, design and test of control system used to monitor and maintain the temperature, relative humidity (RH) and carbon dioxide concentration inside a water jacketed incubator for growing organic cultures. The system hardware was based on the Z80 microprocessor, and included solid-state switching for mains operated heaters. The interior walls and chamber air temperature were monitored using platinum resistance probes, while NDIR (non-dispersive infra-red) absorption sensors were used to monitor and control the CO2 and relative humidity concentration.

Developed a dual air temperature sensor PID algorithm for an ARM processor based direct heat shaker incubator system that actively regulated the spatial temperature distribution to provide exceptionally uniform and gentle convection circulation of the chamber atmosphere, preventing turbulence that could otherwise shock growing cells or rapidly spread contamination as found in fan assisted designs. The fast recovery profile in conjunction with an Active Humidity System (AHS) allowed the temperature, CO2 and RH levels to return to their pre 30 second door opening levels within 15 minutes. The motion of the shaker plate was controlled by a PI feedback algorithm which automatically compensated for the gear ratio variances introduced by the V-belt design of the triple eccentric drive mechanism, allowing single point speed calibration over its entire 25 to 400 rpm range.

Nd-YAG Laser System

Utilised a wide range of academic, analytical and problem solving skills in the development of a highly innovative medical laser system, which was half the size and had a greater power range than its worldwide competition while being manufactured at a much lower cost. Was a key member of the multi-disciplined team with software, hardware, mechanical, optical, laser physics and marketing skills that applied a range of Value Engineering, Brainstorming and Lateral Thinking methods to solve critical engineering and scientific problems.

Designed the analogue electronics interface to allow the laser's continuous wave 1064nm infra-red beam to be detected and its 6KW 3-phase switch mode power supply to be controlled. The real-time multi-tasking software structure, based on a prioritised "round robin" algorithm controlling multiple state machines, was designed to meet British (BS) and German (TUV) safety standards for medical equipment.

The laser beam was stabilised over a wide range of output powers (1-120 watts) by developing an adaptive PI feedback algorithm that was highly optimised using fixed point maths to run at 100us interrupt intervals. To achieve high output accuracy, the detector module automatically compensated for the thermal drift of the infrared sensing photo-diode and took account of the effects of variations within the polarization states of the laser beam itself through an inspired mechatronic design.

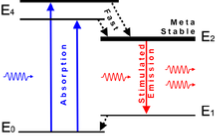

Following detailed analysis of the optical resonator gain profile and atomic energy level decay times, a high speed intelligent software timing sequence overcame the problem of detecting spontaneous emissions which otherwise prevented population inversion when attempting to lase at low output powers.

Following detailed analysis of the optical resonator gain profile and atomic energy level decay times, a high speed intelligent software timing sequence overcame the problem of detecting spontaneous emissions which otherwise prevented population inversion when attempting to lase at low output powers.

Ussing Chamber Control System

Specification, design, build and test of analogue control system for a 4 channel Ussing Chamber unit, used in cystic fibrosis research. Liquid junction electrodes were interfaced to high input impedance instrumentation op-amps to monitor the voltage (uV) generated by the transportation of ions across a tissue sample immersed in oxygenated saline solution. The voltage could be nullified by passing an appropriate current (uA) through the chamber, so that the open and closed loop voltage/current relationships, and hence ion transport characteristics, could be monitored when various drugs were injected into the sample.

Please send comments about this website to webmaster@atc-ltd.co.uk.

Copyright © 2025 Automatic Test & Control Limited. All rights reserved.